In knead of a refresh…

Recently, our team came to the aid of Warburtons bakery who were in need of our refurbishment service.

They required a non-stick coating to be applied to their moulder quadrant and bird cage roller production components. Due to the high production demand, the coating would additionally need excellent wear resistance to withstand continuous usage.

The moulder quadrant, which is used to shape raw dough before it is then placed in a baking tin, is at risk of malfunction if dough builds up on the surface. Such issues would result in production delays due to cleaning of the parts to get the system back in working order.

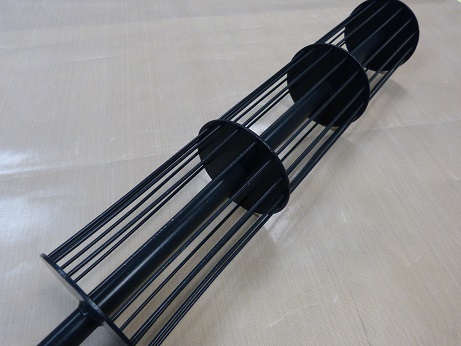

Similarly, the bird cage roller which guides the dough from the divider hopper, would experience issues due to dough build up, causing potential disruption to the production process.

To resolve these problems, we coated both equipment parts with our PR235HB Four Coat Black Sparkle coating as it provides the superior release needed to eliminate the dough sticking issues whilst also delivering the enhanced durability required for the parts.

Prior to coating application, the parts were put through our pyrolysis oven process to breakdown the existing coating and eradicate any dough residues present before being shot blasted. Our PR235HB was then applied by spray application by our skilled team.

Once returned to the customer, Warburtons reinstalled the refurbished parts on production and noted the reduction in sticking issues and subsequent production downtime.

If you have a refurbishment project in need of a non-stick coating solution, contact our sales team today to see how we can help you.

Contact Us